7.3 - Mitsubishi i Miev

Mitsubishi i Miev

Introducing i-MiEV

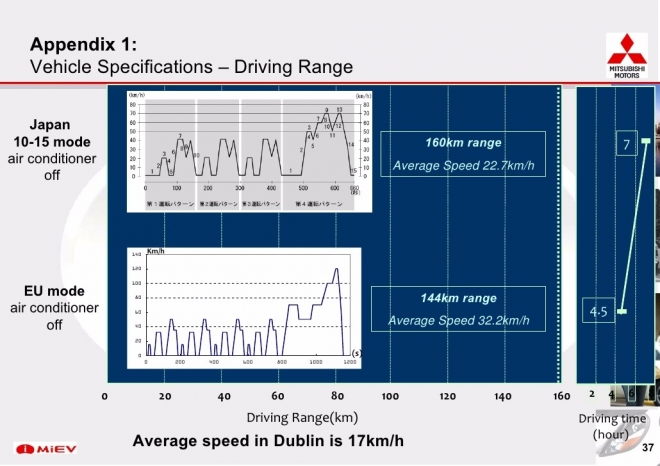

Designed for the urban car environment.

- Like its petrol equivalent it is not designed for long distance commuting.

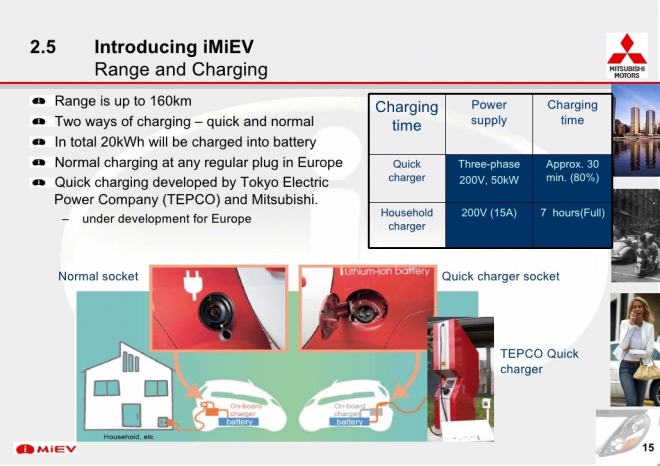

- Range is capped at 160km

Short term supply issues

- Extreme competition from other countries

- Cost of initial production vehicle is high for most consumers

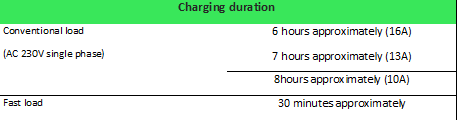

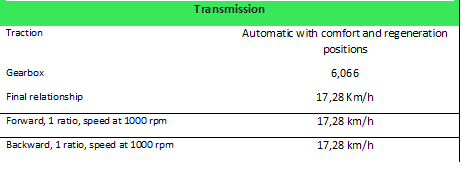

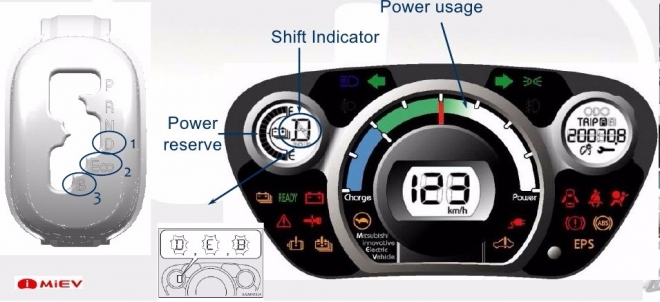

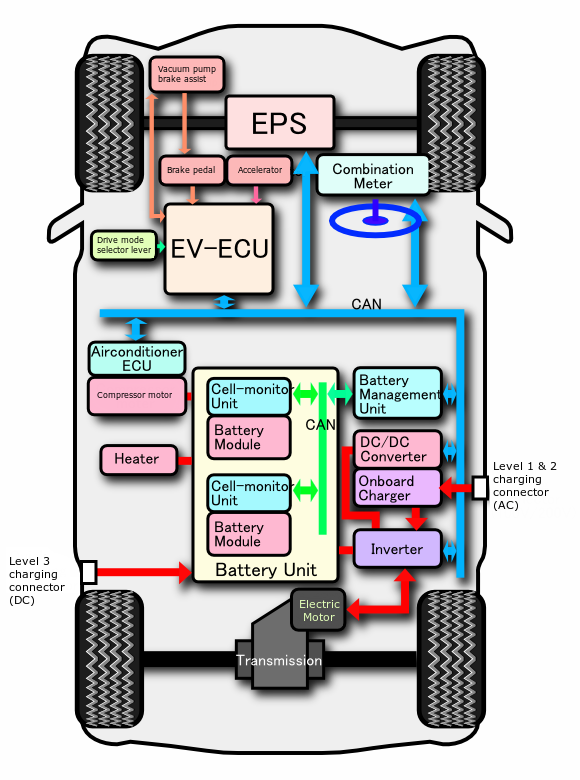

Instrument panel and control. Three positions for gear level:

- Drive – car functions as normal.

- Eco mode - limits power output – so limits consumption. Light regenerative braking

- Brake – strong regenerative braking – used for downhills driving

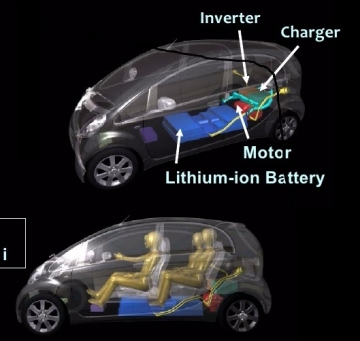

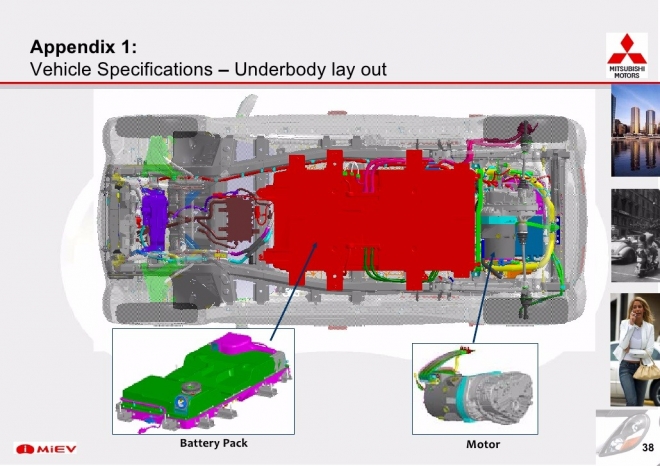

All EV components can be installed under the floor

Systems and components

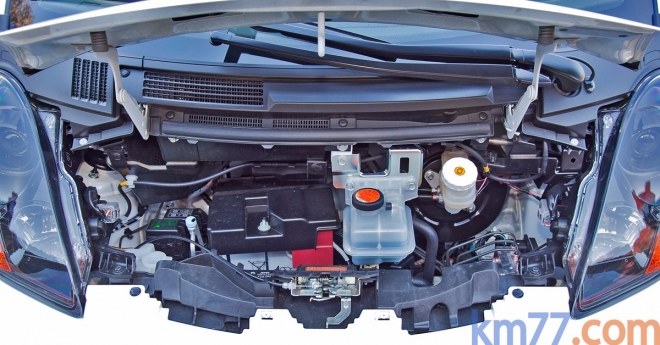

Under the rear load platform. The inverter, rectifier and DC-DC voltage reduction device (For auxiliary battery). The motor, differential and reduction gear assembly are beneath. On the left, the red filler cap is for motor coolant (water antifreeze mix). On the right, the electric vacuum pump for the braking system.

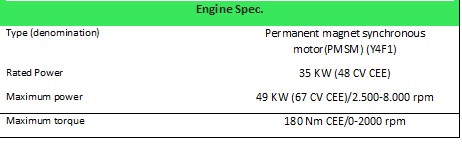

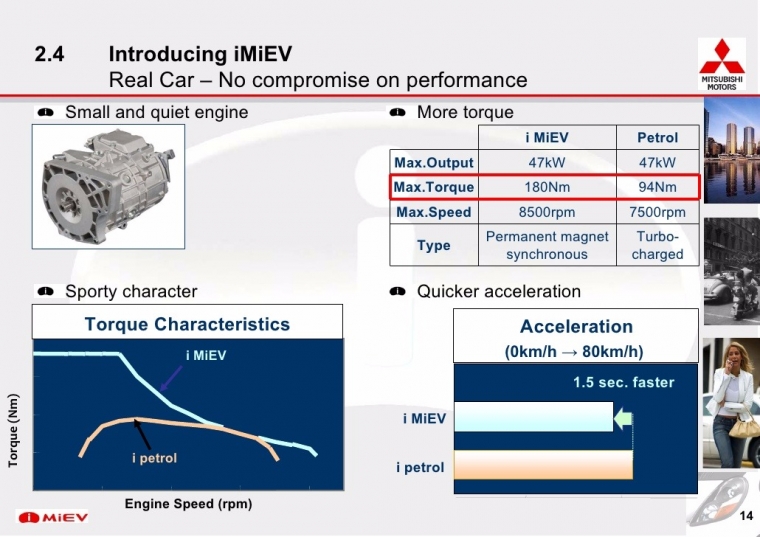

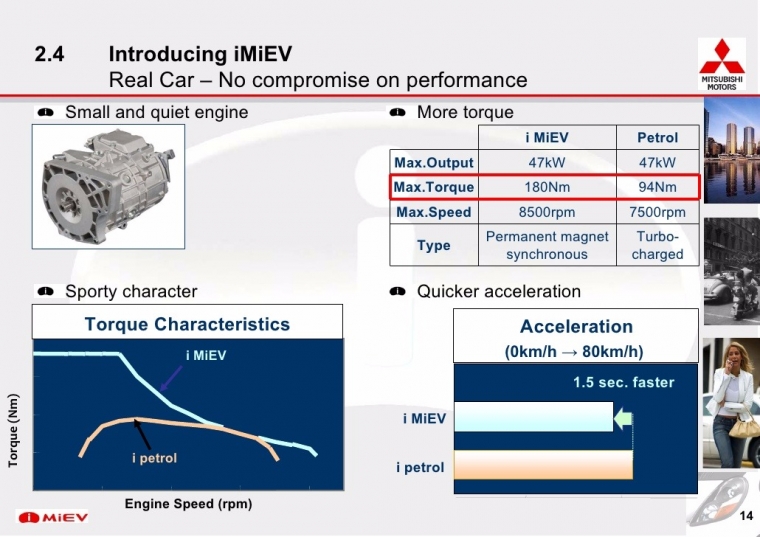

Engine and traction

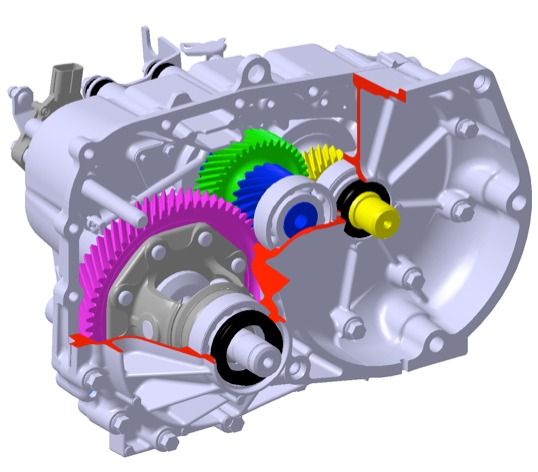

The vehicle uses a single-speed reduction gear transmission driving the rear wheels.

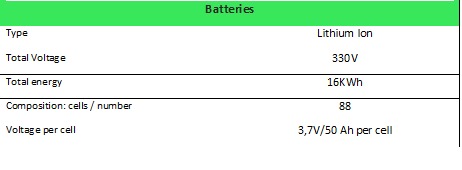

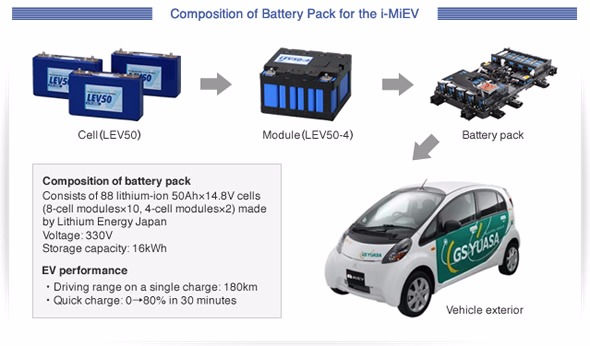

Battery

Cooling

The motor is water cooled, there is a conventional automobile radiator in the front of the car with an electric fan. The coolant (with antifreeze) level is monitored via a tank under the rear load platform on the left hand side of the vehicle

Battery

It includes two types of connectors:

-

Chademo:On the left hand side of the car towards the rear is the “rapid” DC CHAdeMO charging point. at 125 Amps. It is beneath a cover (released from inside the car), there is a dust cover beneath to keep out insects etc. There are two large pins (for the charging current) and eight small ones for control circuitry. The cable used for this purpose is captive to the roadside charging point. When the car is on fast (DC) charge, the air conditioning system is automatically started and refrigerated air is blown through the battery pack for cooling purposes. There is a diverter flap in the ventilation system for this. From depletion, the battery may be charged to 80% full in 20 minutes using this socket.

- Mennekes:On the right hand side of the car is the “fast” and “slow” AC charging point, accessed in a similar way to the DC charge point. This is a five pin IEC62196-2 Type 2 point. Three large pins are the line, neutral and earth/ground. The two small pins are a control circuit. This circuit enables the charge current to be cut off when charging is complete, cuts off power if the plug is removed from the vehicle (the plug and socket are both unshuttered), prevents both rapid and fast charging being done simultaneously and also prevents the vehicle from being driven while the plug is inserted. For “fast charging”, the control box (mounted at the roadside) is limited to 20 amps enabling a charge time (from depletion) of four hours. For “slow charging”, a non-captive lead/cord is provided with the car. It is intended for use in the home or other domestic places. This has a local plug at one end and a Mennekes connector at the other. The Mennekes plug has a retaining trigger with a hole for a padlock to prevent the plug from being removed from the car if deemed necessary. There is a “floating” control box in the middle of this lead/cord that functions similarly to the fast charger but limits current to 10 amps so enabling an eight-hour charge time (from complete depletion on 230 volts)

Maintenance

Frequency of maintenance:

- Normal conditions: 20000 km or 1 year

- Severe conditions: 10000 km or 6 months

Contents of the maintenance plan:

- Control of high voltage cables (every 24 months).

- Traction battery maintenance: update the battery charging capacity of traction at 12 months, and then every 24 months.

- Empty of reducer: every 100,000 km or 5 years.

- Control of liquids (windshield washer, cooling, heating).

- Replacement of brake fluid and pollen filter.

- Generic vehicle controls (functions, low, safety).

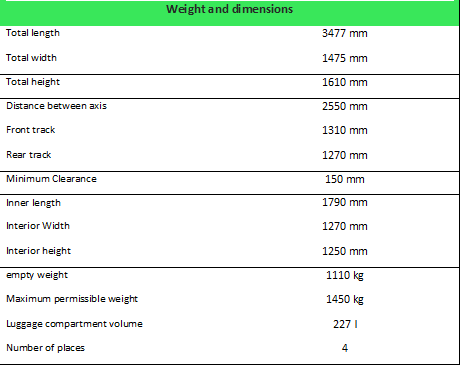

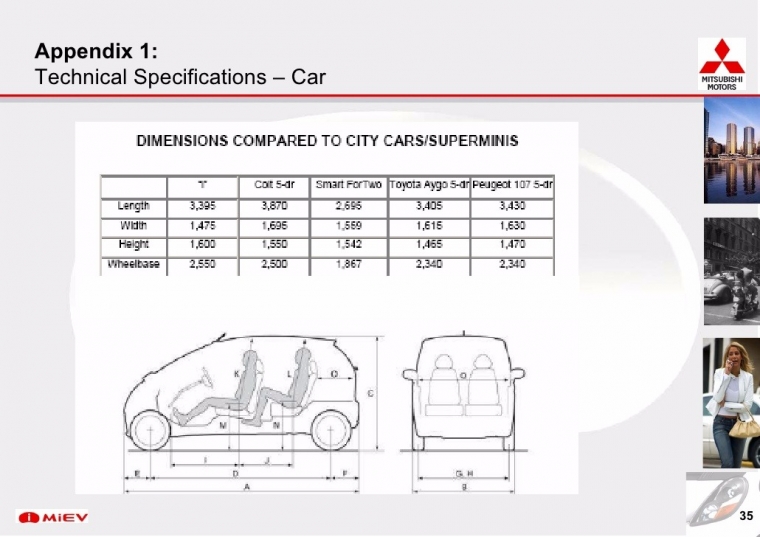

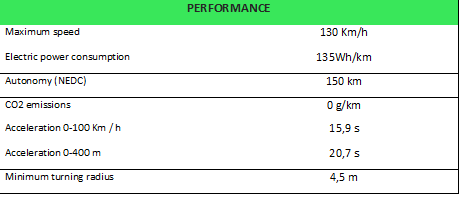

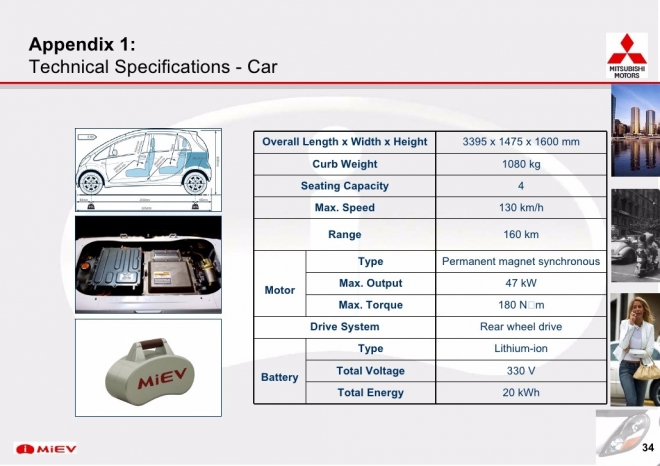

Mitsubishi i-Miev TECHNICAL DATA